Our latest blog provides an 11 point checklist for business best practices related to pest prevention and equipment maintenance. Read more below.

As we have mentioned in many of our previous blogs, we believe that pest control for your business can only be effective if it’s based firmly on the principles of Integrated pest management (IPM).

Integrated pest management employs a combination of practices including current, comprehensive information on the life cycles of pests, their behaviour, biology, and their interactions with their environment to eliminate the root cause of a pest infestation. You can read more about it in this blog post. IPM is based on four principles we call ERDM: exclusion, restriction, destruction and monitoring.

Prevent pest infestation:

Like our previous checklists, this post – which focuses on equipment maintenance – also falls under the restriction component of ERDM. Restriction is all about containing the spread of pest infestations throughout your business through the removal of food and harborage sites. Dirty or poorly maintained equipment is an easy source of food and water for a number of common pests.

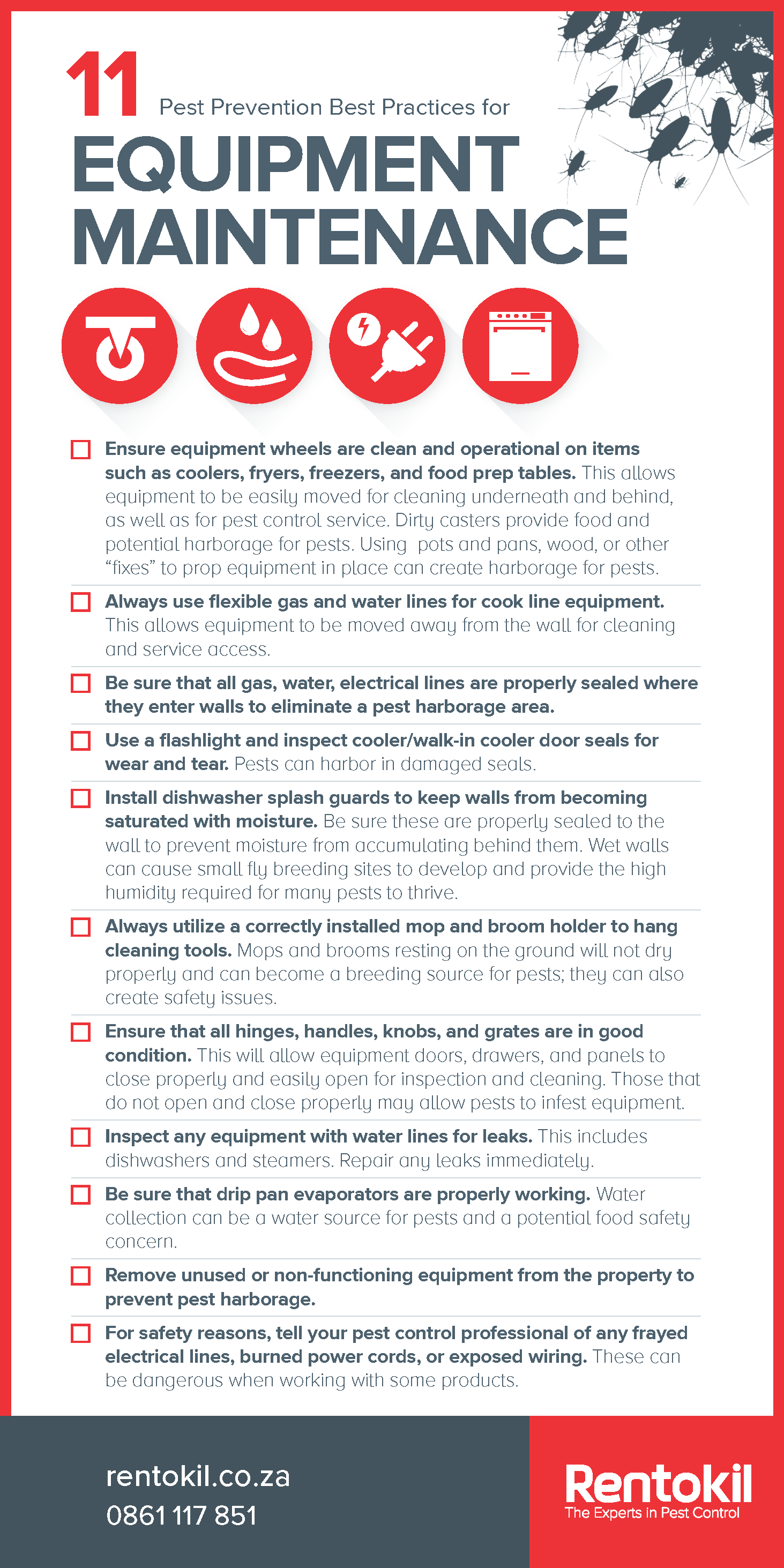

By putting the tips below into practice, you’ll not only be keeping your expensive equipment in tip-top condition, but also restricting pest access to food and water, thus making your premises less inviting and containing the spread of pest infestations throughout your business.

Here are our top 11 pest prevention best practice tips for equipment maintenance:

We’re certain that implementing these best practice tips will be useful to ensure that expensive equipment remains well maintained and your premises remain pest-free. Book a free pest risk survey with one of our pest experts today to ensure that your establishment is completely pest-free.

Leave a Reply